Sherwood

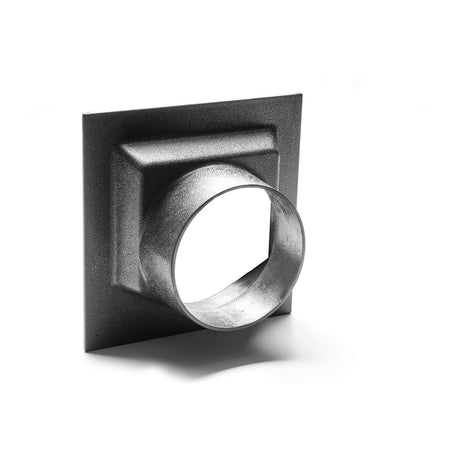

Sherwood Medium Dust Extraction Hood 4in Outlet 340 x 184mm Mouth

$15.90$19.90Unit price /UnavailableIn stockSherwood

Sherwood Large Dust Extraction Hood 4in Outlet 420 x 320mm Mouth

$23.90$29.90Unit price /UnavailableIn stockSherwood

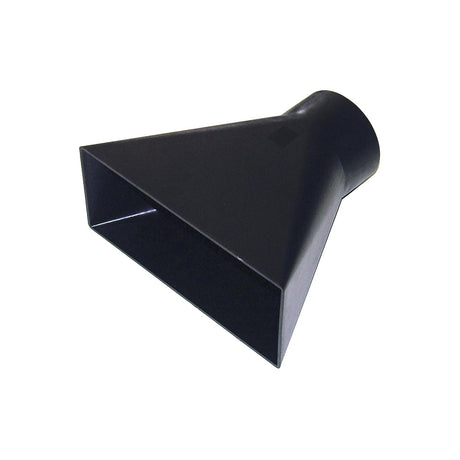

Sherwood Small Dust Extraction Hood 4in Outlet 250 x 110mm Mouth

$15.90$19.90Unit price /UnavailableIn stockSherwood

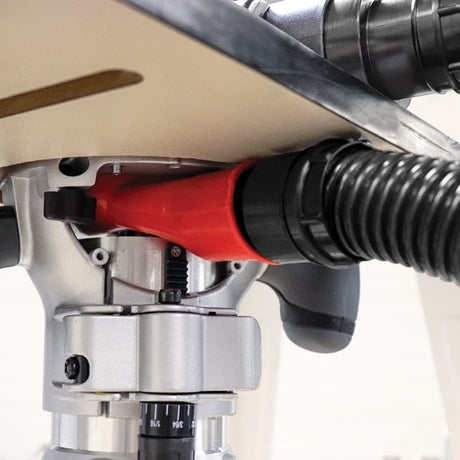

Sherwood 4in Diameter Hold Tite Hose Extraction Kit

$38.50$44.90Unit price /UnavailableIn stockSherwood

Sherwood Dust Extraction Hood Stand Variable Height 4in Duct

$93.50$109.90Unit price /UnavailableIn stockSherwood

Sherwood 4in Angled Dust Extraction Outlet 190 x 100mm

$9.90$11.90Unit price /UnavailableIn stockSherwood

Sherwood Lathe Dust Extraction Hood for Woodturning Dust Collection

$27.90$34.90Unit price /UnavailableIn stockSherwood

Sherwood 4in Dust Extraction Hood Kit with Threaded Splice Connectors

$55.90$64.90Unit price /UnavailableIn stockSherwood

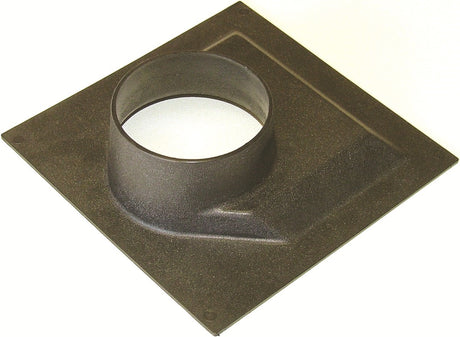

Sherwood 4in Machine Dust Collection Extraction Hood 210 x 210mm

$8.90$10.90Unit price /UnavailableIn stockSherwood

Sherwood Overhead Dust Extraction Guard for SWMS-250 Heavy-Duty Table Saw

$399.00Unit price /UnavailableVery low stock (3 units)Sherwood

Sherwood Overhead Dust Extraction Guard for SWMS-300 Heavy-Duty Table Saw

$399.00Unit price /UnavailableVery low stock (4 units)

Enhance Dust Capture at the Source with Extraction Hoods

Dust extraction hoods are a vital component in controlling airborne dust at its origin in woodworking operations. These hoods are designed to enclose or partially enclose cutting or sanding zones, efficiently directing debris into a dust collection system. By capturing dust as it's generated, extraction hoods significantly reduce airborne particles and improve both workshop cleanliness and air quality.

Available in a range of shapes and sizes, dust hoods can be tailored to fit specific tools like table saws, mitre saws, routers, and sanders. Some models are fully enclosed for maximum containment, while others are open-faced to accommodate larger stock or mobile tool applications. The inclusion of standard port sizes and adaptable flanges ensures easy integration into most dust extraction systems, whether using flexible hose or rigid ducting.

Proper placement of an extraction hood is key to its effectiveness. Positioning the hood as close as possible to the dust source maximises capture efficiency, especially during high-speed machining where dust is ejected at force. For CNC machines or downdraft tables, purpose-built hoods help streamline suction and contain fine particulates that may otherwise linger in the air or settle on surfaces.

Maintenance is minimal but essential—ensure ports and grilles remain free from blockages, and check periodically for any damage to sealing areas. Whether retrofitting to existing setups or designing a new extraction layout, dust extraction hoods are a smart investment that enhances safety, tool longevity, and project finish quality in any woodworking space.

FAQs

What does a dust extraction hood do?

Dust extraction hoods capture airborne dust and debris directly at the source by enclosing or surrounding the tool area. They help funnel dust into your extraction system, reducing airborne contamination and clean-up time.

Are dust hoods compatible with all tools?

Most dust hoods are designed for specific tools or applications, but many are adjustable or can be customised with adaptors. Common tools include table saws, bandsaws, routers, and mitre saws.

How do I install a dust extraction hood?

Installation typically involves mounting the hood near the dust source and connecting it to your extraction system via hose or ducting. Some hoods come with brackets or magnetic bases for tool-free setup.

Can I use a dust hood with a flexible hose system?

Yes, dust extraction hoods are often designed with standard port sizes (such as 100mm or 63mm) that make them compatible with flexible hose connections, allowing for easy integration into most systems.

What size extraction hood do I need?

The size of the hood should correspond to the tool it’s serving and the dust volume it produces. Larger tools or operations that produce more debris will benefit from wider or enclosed hood designs to maximise capture.

How do I improve dust capture with a hood?

Ensure the hood is as close to the dust source as safely possible, with minimal obstructions between the hood and the tool. Using high-suction extraction systems and keeping the airflow path short also helps maximise efficiency.

What materials are dust hoods made from?

Dust hoods are commonly made from ABS plastic, PVC, or steel. Each material offers a balance between durability, weight, and cost, with plastic models being popular for portability and ease of use.