Incra Original Jig with Fence System for Joinery - Metric

Sale ends in:

Incra Original Jig with Fence System for Joinery - Metric is backordered and will ship as soon as it is back in stock.

Request Further Information

Incra Original Jig with Fence System for Joinery - Metric

![]() Eligible for FREE Shipping*

Eligible for FREE Shipping*

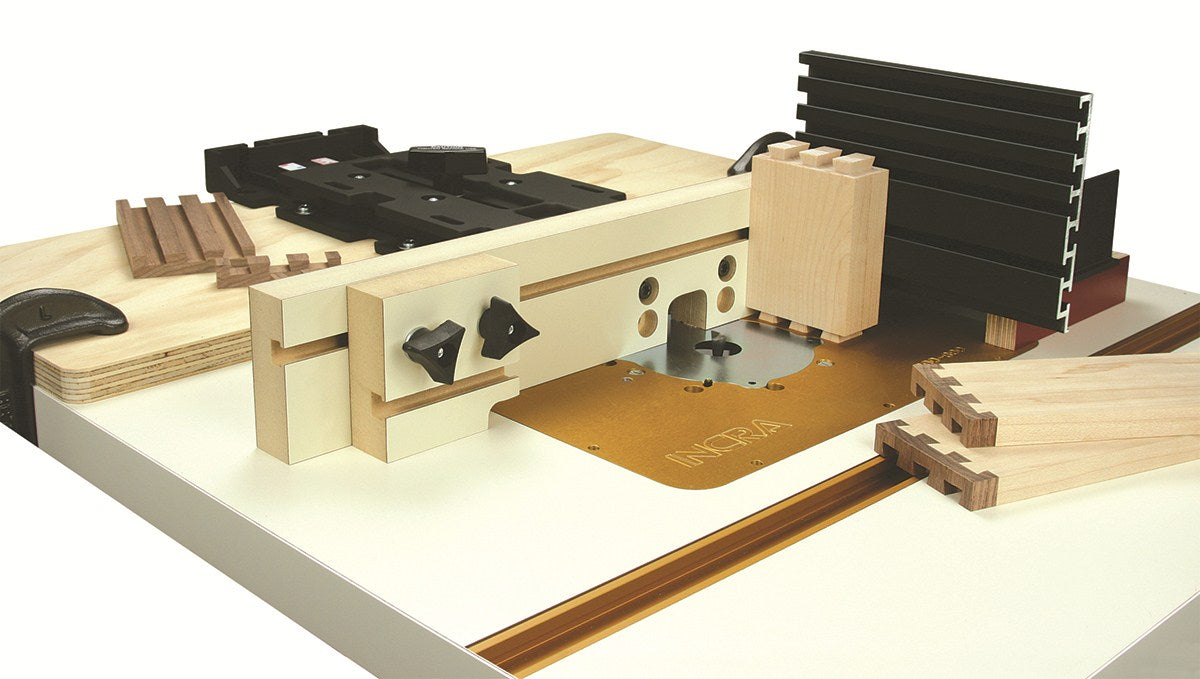

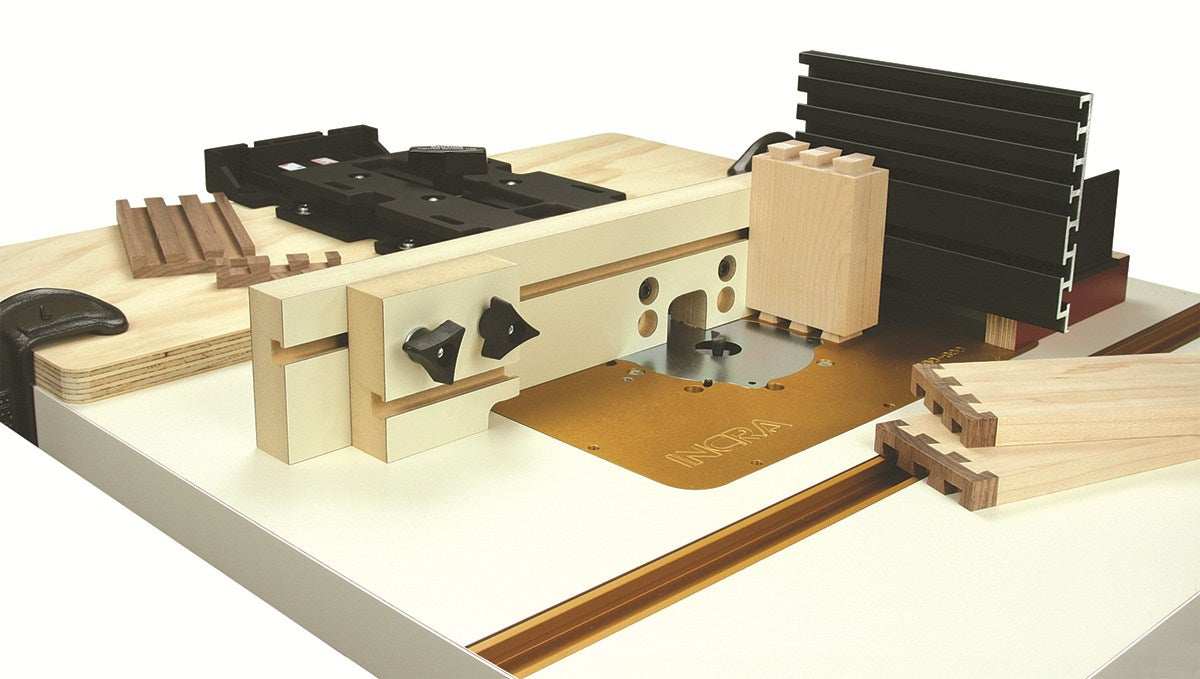

The renowned Original Incra Jig has brand new features!

The Original Incra Jig has been reissued, and the same qualities that made it such a knockout are still relevant in workshops today.

The only two moving parts are the locking knob and the single-piece upper carriage. It indexes on 1.0mm increments with the same 0.025mm positioning accuracy and repeatability of our top-of-the-line LS Positioners – just without the fine adjustment.

Incra Jig, fence positioner, dovetail jig, box joints, bandsaw table, drill press table and more!

The rigid, glass-reinforced resin body provides 200mm of solid fence travel. The patented incremental racks are installed where the halves of the jig meet and when the clamping knob is tightened, the teeth mesh, causing the fence and carriage to instantly “centre up” on the perfect multiples of 1.0mm increments far more precisely than working by eye alone.

Create dovetails with the Incra Jig Fence System

By adding the Incra Jig Fence System, 3/8in box joint and 1/2in dovetails can be produced equally spaced or variably spaced. The dovetail template can be made half-blind, through, sliding, or corner-post.

For even more variety, the 11 box joint templates and 29 dovetail templates from the Incra Master Reference Guide can be adapted to the Original INCRA Jig to produce literally billions of joinery variations. If you need the ultimate in accuracy on other platforms, such as a drill press table or band saw (as shown in the image gallery), then the Original Incra Jig is impossible to beat.

Not just for Box Joints and Dovetails!

And keep in mind that INCRA Jigs aren’t just for box joints and dovetails. The incremental nature of the Jig causes fence setups for any repetitive cutting operations such as grooving and fluting to suddenly become lightning fast and dead-on accurate. Adding a fence with a larger router bit opening makes it simple to remove material in controlled steps when doing everyday edge forming operations.

Though it was made famous by router work, the Original INCRA Jig’s compact size makes it perfect for use at a variety of different machines, really anywhere you have a need for a sturdy, accurate, and repeatable fence positioner. Positioning the fence on a drill press table or re-sawing lumber at the band saw are only two of the possibilities.

Though the value of the reissued Original INCRA Jig hasn’t changed, the rest of the package has benefitted from our 20+ years of experience manufacturing incremental positioners. The printed instructions are clear, concise, and fully illustrated.

The INCRA Fence, Stop & Right Angle Fixture for the Original Jig

The INCRA Original Jig Fence System, Stop & Right-Angle Fixture includes all of the items needed to produce highly detailed box joints and dovetails, as well as hardware and information for creating even more accessories.

The 20in long fence is laminated on both sides and is machined with a front T-slot and a router bit opening measuring 1-1/4in wide x 1in high. Hardware is included and instructions provided for shop-made wooden sub fences that work with the fence’s T-slot to allow larger cutters and a variable-size router bit opening.

The aluminum right angle features a 6-3/4in wide face plate with plenty of T-slots for adding backing boards or other fixtures for specialized work.

The wooden runners are replaceable and gentle on your router bits in the event of accidental contact. The double-laminated stop is use to limit the length of cuts such as the pin cuts on dovetails or stopped grooves for fully-trapped drawer and box bottom panels.

The stop is attached to the fence with quick-action knobs, it’s reversible to offer a choice of stop surfaces and it even features its own T-slot for adding other fixtures.

Features

- Includes all of the items needed to produce highly detailed box joints and dovetails

- It is laminated on both sides

- It is machined with a front t-slot

- Hardware is included and instructions provided for shop-made wooden sub fences

- Allow larger cutters and a variable-size router bit opening