MPOWER Angled Diamond Sharpening Plates for FastTrack Sharpening System

Sale ends in:

MPOWER Angled Diamond Sharpening Plates for FastTrack Sharpening System - 100 Grit - Extra Coarse is backordered and will ship as soon as it is back in stock.

Request Further Information

MPOWER Angled Diamond Sharpening Plates for FastTrack Sharpening System

![]() Eligible for FREE Shipping*

Eligible for FREE Shipping*

A formidable combination in the battle against blunt tools.

Traditionally sharpening chisels and plane blades was a messy business. Usually involving an arkansas oilstone or Japanese waterstone, a lubricant - oil or water, some cloths to clean up the mess afterwards and not forgetting a considerable level of skill; to hold and maintain the contact angle between blade and stone.

Once a decent primary angle has been established the PSS is ideal for creating and re-touching blade edges. The tidy up afterwards is almost nonexistent as the Diamond cross stones can be used dry if preferred. Most important is that the tool is sharp when undertaking a task. A blunt edge is a very dangerous condition to use a tool and even if injury is avoided; the resulting finish is never crisp and ‘’professional’’ looking. The PSS allied with the New Diamond Cross stones is probably the fastest way to safely create and maintain a good sharp edge.

Any successful tool sharpening process will result in a wire or burr forming on the back or flat of a blade. It’s important to remove this wire during (between diamond grades) and finishing the sharpening process. This can be easily done using a Diamond Cross 1000 grade stone wiped flat across the back of the blade.

Routers, like any other woodworking blade need regular sharpening and maintenance. The Diamond Cross Stone is the perfect size to work in between the flat of the TCT blade and the anti chip body of the cutter.

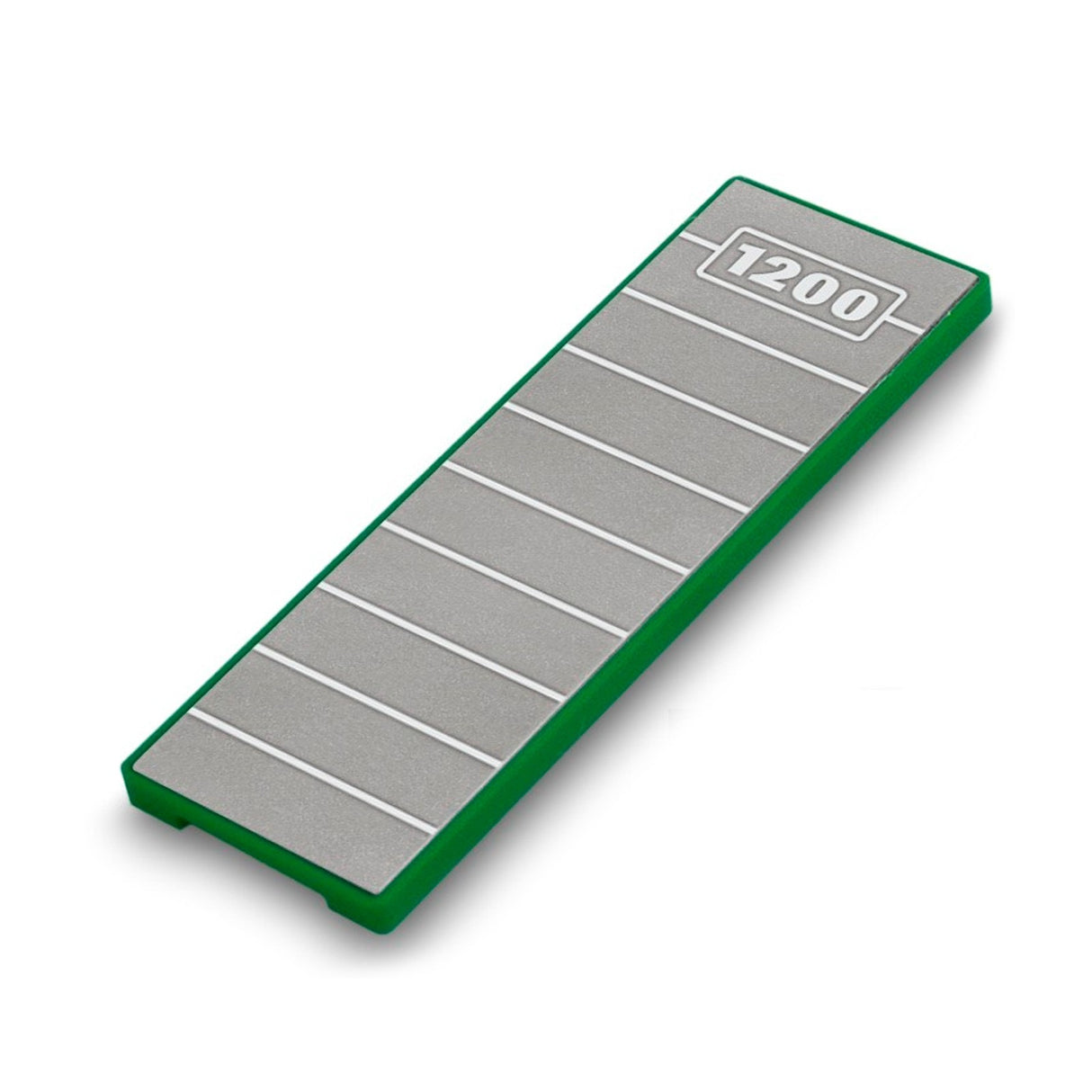

Unique surface pattern

With all diamond sharpening stones pasting can occur. This is where a mixture of debris from the sharpening process mix with dirt to clog the diamond stone surface which reduces the abrasion rate of the stone. This occurs more on a continuous coated diamond surface stone as there is nowhere for the this spent material to go. The diamond cross pattern provides specifically designed relief recesses where the waste material is forced during sharpening thus reducing the pasting effect and reducing the need to frequently clean.

Increased size

The new stones are larger than the originals with an increased sharpening surface area of just over 10%. That means more abrasion, quicker sharpening and better results. Size: 3 x 1” (76 x 25mm)

Finger recessed backing plates

The backing plates are now recessed at both ends to make it easier and quicker to remove from the diamond stone from the PSS carriage when changing over to a different diamond grit. The same backing plate colour to grit coding has been maintained as before.

Diamond grade indication

So there’s no confusion as to what colour of backing plate refers to what grade of diamond. The grade or grit size is clearly relief etched on the top surface at one end of the new stones. So it’s always clear which grade of stone is in your hand.

Please Note: Design may change. Pictures for illustration purposes only.