DeerFos

DeerFos Sanding Belts for 610mm x 100mm Belt Sanders

$4.50Unit price /UnavailableIn stockSherwood

Sherwood Pack of Five Sanding Sleeves for SOS-450-LT

$17.90Unit price /UnavailableIn stockSherwood

Sherwood Pack of 20 Sanding Sleeves Mix of 4 Grits for SOS-450-LT

$64.90$71.60Unit price /UnavailableIn stockMirka

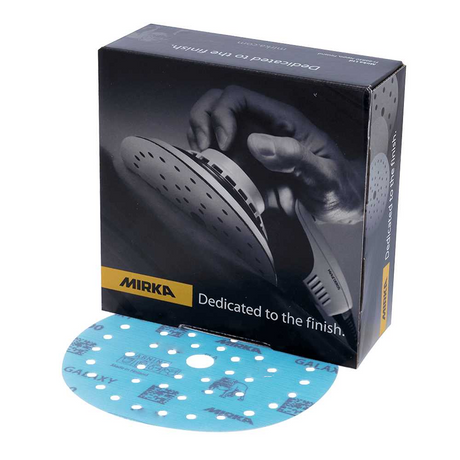

Mirka Galaxy Sanding Disc - 125mm Mix Coarse Pack of 10

$12.00Unit price /UnavailableIn stockDeerFos

DeerFos Abrasive Sanding Discs for 125mm Disc Sanders

$2.00Unit price /UnavailableIn stockSherwood

Sherwood 180 Grit Sandpaper Abrasive Roll for SWD-660-TW

$16.90Unit price /UnavailableIn stockSherwood

Sherwood 80 Grit Sandpaper Abrasive Roll for SWD-406-L

$12.90Unit price /UnavailableIn stockMirka

Mirka Galaxy Sanding Disc - 150mm Mix Coarse Pack of 10

$15.00Unit price /UnavailableIn stockMirka

Mirka Abranet Ceramic Sanding Sheet - 81 x 133mm Pack of 10

$22.00Unit price /UnavailableIn stockMirka

Mirka Abranet Ace Heavy-Duty Ceramic Sanding Disc 150mm 25 Pack

$71.90Unit price /UnavailableLow stock (10 units)Sherwood

Sherwood Pack of Five Sanding Sleeves for BOS-450-T

$17.90Unit price /UnavailableIn stock

Sandpaper & Other Abrasives

Timbecon's range of sandpaper and coated abrasives offer a comprehensive selection for all your woodworking projects. Our collection encompasses a variety of grits and types of sanding paper, ensuring you find the perfect match for any task, from rough material removal to delicate finishing touches. Quality is paramount in our selection, allowing you to buy quality sandpaper online with confidence, knowing it will meet the demands of your woodworking needs.

Choosing the right sandpaper involves considering the grit size—lower numbers are coarser and suitable for initial sanding, while higher numbers are finer and ideal for finishing surfaces. The backing material of the sanding paper also plays a crucial role, influencing its durability and suitability for different applications, whether you're hand sanding or using a machine.

For those looking to achieve the smoothest finishes or tackle specific projects, Timbecon's sandpaper range also includes specialised abrasive papers designed for various applications, from shaping wood to preparing surfaces for finishing. Remember to pair your sandpaper with the appropriate tools for optimal results, such as hand sanders for manual and profiled work or orbital sander pads for powered sanding.

Explore our extensive selection today and elevate your woodworking with the right sanding solutions. Discover the difference quality sandpaper can make to your projects and browse our accessories, including hand sanders and orbital sander pads, to complete your sanding toolkit.

FAQs

How do I determine the appropriate grit sandpaper for my finishing project?

Selecting the appropriate grit sandpaper for your finishing project involves understanding the stages of sanding: starting coarse for material removal and progressing to fine for smooth finishes. For rough surfaces or removing old finishes, begin with a grit between 60 and 80. As you prepare the wood for finishing, transition through medium grits (100-150) to eliminate any scratches or imperfections. Before applying the finish, the final sanding should use fine grits, such as 220 to 320, ensuring a perfectly smooth surface. Test the sanded area by running your hand across it; it should feel smooth without any noticeable blemishes or roughness.

How can I tell when I've sanded enough?

Knowing when you've sanded enough comes from observing the uniformity and feel of the surface. The project piece should have a consistent appearance, with no visible marks, scratches, or unevenness. The surface should feel smooth to the touch, without any gritty texture. Using a light source at an angle can help reveal imperfections missed at a glance. Achieving a uniform, smooth surface indicates you've sanded sufficiently.

How often should sandpaper be changed?

The frequency of changing sandpaper depends on the material you're sanding and the paper's quality. Hardwoods and painted surfaces tend to wear down sandpaper more quickly than softwoods. A decrease in sanding efficiency or visible clogging of the sandpaper are clear indicators it's time for a change. High-quality sandpaper with anti-clog coatings will last longer, but it's essential to assess the paper's condition continuously and replace it as soon as it stops performing effectively to ensure the best results and minimise effort.

How do I prevent and remove clogging in my sandpaper?

Preventing clogging in sandpaper involves selecting the right grit for the material and ensuring the sandpaper has an anti-clog coating. Regularly remove the build-up of dust and debris during sanding by tapping the sandpaper against a hard surface or using a rubber cleaning stick designed for this purpose. If clogging occurs, gently brushing the surface with a wire brush or cleaning block can dislodge embedded particles. Keeping the sandpaper clean enhances its lifespan and effectiveness.

Is sandpaper actually made from sand, or a different material?

Modern sandpaper is not made from sand but rather from engineered abrasives like aluminium oxide, silicon carbide, or ceramic grains, which are bonded to a paper, cloth, or film backing. These materials are chosen for their durability and cutting efficiency. The term "sandpaper" persists from early versions of the abrasive, which used natural materials like crushed shell, glass, and sand.

What grit sandpaper should be used to remove stains and paint from wood?

Removing stains and paint from wood effectively requires starting with medium grit sandpaper, around 80 to 100, to strip off the top layers without damaging the wood underneath. After the majority of the stain or paint is removed, switch to a finer grit, such as 150-220, to smooth the surface and prepare it for a new finish. The specific grits might need adjustment based on the paint or stain's thickness and the wood's hardness.

What is the lowest and highest grit sandpaper suitable for woodwork?

For woodwork, sandpaper grit can range from very coarse (as low as 40 grit) for rapid material removal and surface levelling to very fine (up to 600 grit or more) for achieving ultra-smooth finishes and preparing surfaces for staining or sealing. The choice of grit depends on the project's requirements and the desired finish quality.

What grit sandpaper should be used as the final step before finishing my project?

For the final sanding step, use a fine grit sandpaper, typically between 220 and 320, before applying a finish to your project. This ensures the wood surface is smooth and ready to accept the finish, contributing to a high-quality final appearance. However, avoid sanding with too fine a grit, as it may polish the wood, making it less receptive to stains and finishes. Aim for a balance that smooths the wood while maintaining its ability to absorb the finishing product effectively.

Is steel wool finer than sandpaper, and what is its grit equivalent?

Steel wool can be considered finer than coarse sandpaper, especially at higher grades. Steel wool's finest grades, such as #0000, are used for ultra-smooth finishes, equivalent to 400 grit sandpaper or above. It's particularly useful for applying finishes or final surface preparation after sanding with sandpaper. Each grade of steel wool serves a specific purpose, from removing paint (coarser grades) to polishing (finer grades).

Do you sell sanding blocks and tools to attach my sandpaper to?

We offer a selection of sanding blocks and attachment tools designed to secure your sandpaper efficiently. These accessories help you sand smoothly and evenly, make it more comfortable to hold and use, and help you sand accurately in different projects. Whether you're hand-sanding a piece of furniture or preparing a surface for finishing, our sanding blocks and tools provide the support you need to achieve a flawless finish.

How do I know when it's time to replace my sandpaper?

You'll know it's time to replace your sandpaper when it shows signs of wear, such as diminished effectiveness, visible smoothness where the abrasive surface used to be, or when it takes more effort to remove material. If the sandpaper begins to tear or if the backing starts to degrade, it's also a clear indication that a replacement is necessary. Keeping your sandpaper in good condition ensures efficient and high-quality sanding results.

What are the safety precautions when sanding?

When sanding, it's essential to prioritise your safety by wearing safety goggles and a dust mask to protect yourself from airborne dust and debris. This simple precaution helps prevent irritation or injury that could occur from particles. Keeping a clean workspace is also important, as it minimises dust buildup and associated risks and hazards.