Melbourne Tool Company

Melbourne Tool Company Low Angle Block Hand Plane

$165.00Unit price /UnavailableIn stockMelbourne Tool Company

Melbourne Tool Company Low Angle Jack Plane Plus Additional Blades

$399.90$448.80Unit price /UnavailableIn stockMelbourne Tool Company

Melbourne Tool Company Low Angle Block Plane Plus Additional Blades

$239.90$254.80Unit price /UnavailableIn stockMelbourne Tool Company

Melbourne Tool Company Cabinet Scraper Carbon Steel Ergonomic Handles

$99.00Unit price /UnavailableIn stockMelbourne Tool Company

Melbourne Tool Company Set of Two Small & Large Router Hand Planes

$339.90$368.00Unit price /UnavailableIn stockMelbourne Tool Company

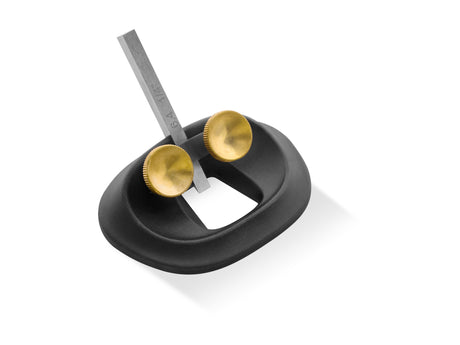

Melbourne Tool Company Small Router Hand Plane Grooving Tool

$119.00Unit price /UnavailableIn stockMelbourne Tool Company

Melbourne Tool Company Flat Sole Spokeshave Ergonomic Handles HSS Blade

$135.00Unit price /UnavailableIn stockLuban

Luban Side Rabbet Plane Vertical Groove Trimmer

$119.90$139.90Unit price /UnavailableIn stockCrown

Crown Traditional Cabinet Scrapers Set of 3 Rectangle Convex Gooseneck

$44.90Unit price /UnavailableIn stockKirschen

Kirschen Cabinet Scraper Set in Leather Wallet with Burnisher

$80.90Unit price /UnavailableIn stockCrown

Crown Traditional Cabinet Scraper Rectangle 0.9 x 152 x 63mm

$17.50Unit price /UnavailableVery low stock (3 units)Narex

Narex Tapered Burnisher for Card Scrapers and Cabinet Scrapers

$54.90Unit price /Unavailable

Hand Planes

Hand planes are essential tools for any woodworker, blending tradition with functionality to shape, smooth, and trim wood with precision and ease. With its sharp blade fixed within a solid body, a hand plane allows for meticulous control over wood removal, enabling craftsmen to achieve a flawlessly smooth surface or perfect fit that machines alone often cannot match. The hand wood planer is cherished for its ability to provide a tactile connection to the woodworking process, offering satisfaction with every pass.

The benefits of using a hand plane include enhanced accuracy in fitting and finishing, the ability to work with the wood grain for superior results, and preserving the wood's integrity. For woodworkers looking to expand their toolkit with versatile and reliable tools, explore our collection of bench planes, which offer additional stability and surface area, making them ideal for larger projects and ensuring your woodworking is both enjoyable and of the highest quality.

FAQs

What are the main types of hand planes?

The main types of hand planes include the chisel plane, block plane, shoulder plane, smoothing plane, jack plane, fore plane, jointing bench plane, and specialised types like the carvers spoon plane and knuckle cap models. Each type serves a unique purpose, from detailed carving to smoothing and shaping wood surfaces. Their diverse functionality makes them indispensable tools for various woodworking projects, ensuring precision and a high-quality finish.

How do I choose the right hand plane for my woodworking project?

Choosing the right hand plane for your woodworking project involves understanding the specific requirements of your work. A smoothing plane is your best bet for tasks requiring a fine, smooth finish. If you want to remove more material over a larger surface, a jack plane offers versatility and efficiency. For precision work, such as fitting joints or working close to edges, a block plane, shoulder plane or chisel plane might be ideal. Consider the size of the project and the level of detail needed, as well as the type of wood you'll be working with. You should also consider your comfort and experience level when using hand planes, as some may require more skill to use effectively. Taking these factors into account will help ensure you select the hand plane that best meets the needs of your project, making your woodworking both enjoyable and successful.

What is the best angle for my hand plane blades?

The best angle for hand plane blades varies depending on the task. Low angles around 25-30 degrees are excellent for end grain and fine work. A general-purpose angle of 45-50 degrees suits most smoothing and planing tasks, while higher angles, from 50 to 55 degrees or more, are preferable for working with difficult grains to prevent tear-out. The correct angle ensures efficiency and the best possible finish.

Are the hand planes at Timbecon suitable for both beginners and experienced woodworkers?

The hand planes at Timbecon cater to both beginners and experienced woodworkers. Beginners will find user-friendly models that are easy to adjust and handle, while seasoned craftsmen can select from high-quality, precision-engineered hand planers that offer exceptional control and durability for complex projects.

What are the key features and qualities to consider when selecting a hand plane?

When selecting a hand plane, consider the build quality, blade material, adjustability for depth and alignment, comfort of the handle, and the specific type suited to your tasks (e.g., smoothing, shaping). High-quality materials and precise manufacturing ensure durability and accuracy, while ergonomic design enhances user comfort during extended use.

Can I find replacement blades and accessories for hand planes on Timbecon's website?

Timbecon offers a comprehensive selection of replacement blades and accessories for hand planes, ensuring you can maintain and enhance your tool's performance. From sharpening tools to additional blades, you can find everything needed to keep your hand planer in top condition.

Are your hand planes ready to use out of the box?

While our Melbourne Tool Company planes in this collection come with a pre-sharpened blade, some sharpening may be necessary to achieve the optimal edge for most tasks straight out of the box. This minor preparation ensures your hand planer is ready for precise woodworking tasks.

How do I sharpen my plane blades?

Sharpening plane blades involves a few key steps: flattening the back of the blade on a coarse stone, honing the bevel on a medium stone, and finally polishing on a fine stone or strop. Using a honing guide can help maintain the correct angle. Regular maintenance keeps the blade sharp for smoother cuts and less physical effort.

How do I prevent tear-out when using a hand plane?

Preventing tear-out with a hand wood plane involves ensuring the blade is sharp, adjusting the cutting angle for the task, and planing in the direction of the wood grain. Using a well-tuned plane and opting for a slightly higher blade angle can help minimise tear-out, especially on figured or tricky grains. Proper technique and tool setup are vital to achieving clean, smooth surfaces.

What maintenance do my hand planes need to keep them in optimal shape?

Maintaining your hand planer involves cleaning to remove any wood residue, sharpening the blade to keep it cutting efficiently, and occasionally oiling the moving parts to ensure smooth adjustment. Protecting the plane from moisture and storing it in a dry place will help prevent rust and ensure it remains in good condition for years to come.

How should I store my hand planes?

Store your woodworking hand planer in a dry, dust-free environment to protect them from moisture and rust. Laying them on a flat surface or hanging them by the handle keeps them safe from damage. Applying a light coat of oil to the blade and exposed metal parts can further protect against rust.

Can I use your hand planes on materials apart from wood?

Hand planes are designed for wood, using hand planes on materials they're not intended for, like metals or hard plastics, can damage the blade and the plane's body. It's best to use the hand planer for its intended purpose to ensure longevity and optimal performance.