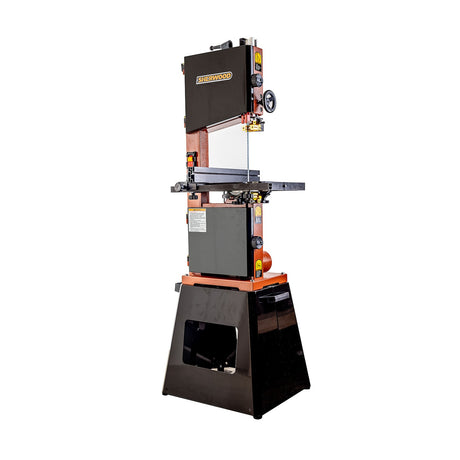

Sherwood

Sherwood 14in 1100W Standard Bandsaw

$1,249.00Unit price /UnavailableVery low stock (1 unit)PROXXON

PROXXON MBS-240/E 6.5in Micro Bandsaw 85W Variable Speed

$768.90Unit price /UnavailableVery low stock (2 units)Sherwood

Sherwood 18in 3000W 4HP Heavy-Duty Bandsaw

$3,799.00Unit price /UnavailableLow stock (7 units)Sherwood

Sherwood 24in 4000W 5HP Industrial Bandsaw 3-Phase

$4,999.00Unit price /UnavailableVery low stock (1 unit)Sherwood

Sherwood 10in 750W Heavy Duty Bandsaw with Sanding System

$1,799.00$1,868.00Unit price /UnavailableLow stock (6 units)Sherwood

Sherwood 20in 3000W 4HP Industrial Bandsaw

$4,199.00Unit price /UnavailableVery low stock (3 units)

Bandsaws

Discover the versatility and precision of Timbecon's bandsaw collection, designed to meet various woodworking needs. Wood bandsaws are essential tools for making straight, curved, or irregular cuts with ease. Ideal for resawing, intricate curved cuts, and detailed joinery, these saws offer unparalleled flexibility in the workshop. Featuring robust construction and adjustable settings, Timbecon's bandsaw machines ensure smooth, accurate cuts on diverse wood types and sizes.

Elevate your woodworking projects with Timbecon's bandsaw collection available for all Australian woodworkers. Browse our extensive range of handsaws, coping saws and other cutting tools to find the perfect match for every task.

FAQs

What is the primary function of a bandsaw in woodworking?

The primary function of a bandsaw in woodworking is to provide versatile cutting capabilities. It's ideal for making precise straight cuts, resawing lumber into thinner slabs, and cutting intricate curves and shapes. The continuous band blade allows for uniform cutting action, making it suitable for various woodworking projects.

How does a bandsaw differ from other types of woodworking saws?

Bandsaws differ from other woodworking saws in their design and cutting action. They use a thin, continuous looped blade that cuts through material with a consistent, uniform motion. This design allows for more intricate cuts, including curves, which are challenging with other saw types. Bandsaw machines also excel in resawing tasks and handling thicker materials.

What should be considered when selecting the appropriate size and type of bandsaw for a workshop?

When selecting a bandsaw for your workshop in Australia, consider the maximum width and thickness of the material you plan to use, as well as the types of cuts you'll be making. The throat size determines how wide a cut you can make, while the motor power impacts the saw's ability to cut through thicker or more challenging materials. Also, consider the space in your workshop, as bandsaws come in various sizes.

How do you set up and adjust a bandsaw for precise and accurate cuts?

Set up and adjust a bandsaw by ensuring proper blade tension and tracking. The blade should run smoothly on the wheels and properly align with the guides. Adjust the guide bearings so they're close to the blade without touching it. Ensure the table is square to the blade and the fence is parallel to the blade's path for straight cuts.

What are the essential safety precautions to observe while operating a bandsaw?

When operating a bandsaw machine, always wear safety glasses and hearing protection. Keep fingers away from the blade and use push sticks for small pieces. Ensure the blade guard is adjusted correctly, and never leave the saw running unattended. Always turn off and unplug the saw when adjusting or changing the blade.

What power requirements do I need to run your bandsaws?

The power requirements for running our bandsaw machines depend on the specific model. Most bandsaws for home workshops run on standard household power of 240V, while larger, industrial models may require 3 phase power. Make sure to check the specifications of the bandsaw model you're looking at for its exact power requirements.

What Personal Protective Equipment (PPE) should I be wearing when operating a bandsaw?

While operating a bandsaw, wear safety glasses or goggles to protect your eyes from flying debris. Ear protection is also recommended to guard against noise. Depending on the nature of the work, a dust mask or respirator might be necessary to prevent inhalation of sawdust.

How do you determine the right blade tension on a bandsaw?

The proper blade tension on a wood bandsaw is crucial for precise cutting. It can be determined by adjusting the tension until the blade is firm and doesn't deflect easily when pushed sideways. Many bandsaws have a tension gauge, but it's also advisable to refer to the blade manufacturer's recommendations and perform a "pluck test" for an audible tone.

Can bandsaws be used to cut materials other than wood, and if so, which ones?

Bandsaws can cut materials other than wood, including metal, plastic, and composite materials, with the appropriate blade type. Blades designed for metal cutting are typically made from stronger materials like bi-metal or carbide and have different tooth configurations suitable for the material's hardness.

What are the benefits of using a bandsaw over other types of saws for resawing and curved cuts?

Bandsaws excel in resawing and curved cuts due to their blade design and cutting mechanics. They provide a smoother cut with less waste compared to table saws in resawing. For curved cuts, choosing a thin blade allows for tighter radii and more intricate designs that are difficult to achieve with other saw types.

How do you maintain and care for a bandsaw to ensure its longevity and optimal performance?

Maintain a bandsaw by regularly cleaning it to remove sawdust and debris, especially from the blade and wheels. Lubricate moving parts as needed and check for blade wear, replacing blades when they become dull. Regularly inspect and adjust the blade tension and alignment and ensure all safety features function correctly.

What factors influence the cut speed and feed rate when using a bandsaw?

Factors influencing cut speed and feed rate on a bandsaw machine include the blade's TPI and thickness, as well as material hardness and thickness. A higher TPI blade cuts slower but smoother, which is ideal for harder or thicker materials. The bandsaw's motor power and blade condition also affect the cutting speed. Adjusting the feed rate to match these factors ensures efficient and clean cuts.

What is the runout on your bandsaws?

The runout on bandsaws refers to the deviation of the blade from its intended path, typically measured in thousandths of an inch. Our bandsaws available across all Australia are designed to minimise runout, ensuring precise and straight cuts. The exact runout specification varies by model, but it's maintained within tolerances that provide high-quality, accurate cutting performance.